Why Does ReechCraft Use a Gearbox and Drill?

For over 30 years, ReechCraft has been a top innovator in the access industry. We strive to solve even the most difficult access problems with new and improved products. However, we are frequently asked why we choose to use a gearbox and drill to power our access equipment. There are multiple reasons for this, and we are excited to share them with you!

Portable & Familiar

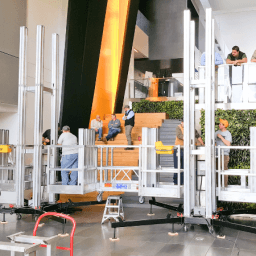

Our products are designed carefully and intentionally to be as portable as possible. The components are made of lightweight aluminum and strong, durable steel, allowing for portability and ease of use. Keeping the power source from adding excessive weight was crucial, and the drill and gearbox system proved to be a reliable solution. Additionally, drills are a common tool on the jobsite, making the system easy and familiar to use for workers.

Low-Maintenance

We know downtime costs you money. That is why we manufacture our access solutions to require minimal maintenance and upkeep. Separating the motor from our drill-operated products makes for cost-effective repairs. If a problem does occur, the gearbox components are easy to service and replace. This allows us to leverage the reliability of drills and give that value directly back to the user.

Simple Design

Finally, our proprietary PowerTrak system is an extremely simple power transmission solution. The gearbox uses top-of-the-line internal components that have a long life, and the mechanics are straightforward. By making the design and operation of our systems uncomplicated, we can provide products that maintain high-quality performance while keeping the cost of ownership very low.

What Type of Drill Should You Use?

For our PowerLift, you can use a corded or cordless drill. If you choose cordless, we suggest an 18-20v cordless drill with two 5Ah lithium-ion batteries. To power our PowerMast and PowerPole, we recommend a corded, 120v, 8–9-amp, 1/2-inch drill with a keyed chuck and an RPM of 2500-3500. These are typically hammer drills, which are more powerful and last longer. Ensure the hammer function is turned off to reduce premature wear to the system.

About ReechCraft

Since our founding in 1993, ReechCraft has set itself apart with innovative products and first-rate services. We strive to find new access solutions to meet the needs of every craftsman. If you have questions about any of our American-made products, have a custom application, want to place an order or would like additional information about our dealer program, give us a call at (888) 600-6160 or fill out our online contact form.