Why Facility Maintenance Managers Are Turning to the ReechCraft PowerLift

As a Facility Maintenance Manager, your job is to keep operations running smoothly, safely, and efficiently—often with limited staff, tight budgets, and a wide range of responsibilities.

Whether you’re managing a school, hospital, church, stadium, campus, or office complex, your team is constantly tasked with accessing hard-to-reach areas for lighting, HVAC, electrical, painting, and general upkeep. Traditional ladders, scaffolding, and scissor lifts often fall short—literally and figuratively.

That’s where the ReechCraft PowerLift comes in— an innovative access solution that helps your team tackle elevated maintenance tasks with greater safety, speed, and efficiency, all while reducing strain on your staff and resources.

The Realities of Facility Maintenance

Facility maintenance teams are expected to:

- Respond quickly to service requests and minimize downtime and disruption

- Work across diverse environments—from boiler rooms and atriums to narrow hallways

- Work around fixed obstacles like seating, desks, or machinery

- Perform tasks at height with limited manpower

- Ensure safety of workers and people in the vicinity while maintaining productivity

Traditional access equipment like ladders and scaffolding often slows your team down, introduces safety risks, and requires multiple personnel to operate. That’s where the ReechCraft PowerLift changes the game.

The PowerLift addresses all of these pain points with a compact, portable, and highly efficient design.

Why Facility Managers Choose the PowerLift

1. Do More with Fewer People

Problem: Maintenance teams are often small and stretched thin, with long lists of tasks to complete daily.

PowerLift Solution:

- One-person transportation, setup, and operation mean fewer staff are needed to complete elevated tasks.

- Quick deployment in just minutes allows technicians to move from task to task without wasting time on set up or teardown.

2. Enhanced Safety with Hands-Free Operation

Problem: Falls from ladders and unstable platforms are a leading cause of workplace injuries, increasing liability and insurance costs.

PowerLift Solution:

- Provides a stable, enclosed platform that allows technicians to work with both hands safely. It also includes a tool tray, keeping essential tools within reach and reducing the risk of drops or trips.

- Reduces the need for ladders and scaffolding, which are more prone to accidents.

3. Minimize Disruption in Occupied Spaces

Problem: Maintenance often needs to be done during business hours or in sensitive areas like hospitals, schools, or offices.

PowerLift Solution:

- Compact and simple operation minimizes disruption to occupants.

- Non-marking wheels allow for quiet mobility while protecting the flooring in gyms, hallways, and lobbies.

4. Access in Any Environment

Problem: Many facilities have hard-to-reach areas—above stairwells, between seating, over uneven floors, or in narrow corridors.

PowerLift Solution:

- Modular base options allow you to customize your equipment for your environment—tight spaces, uneven surfaces, or areas with obstacles.

- Slim profile allows access up to 24 feet in confined or obstructed areas.

- Easily navigate around furniture, equipment, bleachers, or architectural features.

5. Drill-Powered Flexibility

Problem: Maintenance must be completed in different environments, sometimes without power, to ensure safety while completing electrical or mechanical tasks.

PowerLift Solution:

- The PowerLift can be operated using a cordless drill, giving your team flexibility without sacrificing performance.

6. Compact and Portable

Problem: Traditional access equipment like boom lifts and scaffolding are cumbersome, hard to transport, and expensive to store.

PowerLift Solution:

- Disassembles quickly to fit through standard doorways and effortlessly maneuver around tight corners.

- PowerLift’s aluminum frame, non-marking transport wheels, and modular components make it easy for one person to move from location to location.

- No trailer required for transport between jobsites with the convenient Hitch Hauler.

7. Budget Constraints

Problem: Facility budgets are tight, and renting or maintaining large equipment can be costly.

PowerLift Solution:

- Cost-effective alternative to scissor lifts or scaffolding.

- Reduces rental fees and labor costs over time with increased efficiency.

PowerLift Use Case: Multi-Site Maintenance Made Easy

A regional facility manager overseeing multiple office buildings shared how the PowerLift streamlined their operations. Instead of coordinating lift rentals at each site, they equipped their mobile maintenance team with a PowerLift.

The result? Faster job completion, fewer crew members, and zero floor damage.

The Bottom Line: Smarter Access for Smarter Facilities

The ReechCraft PowerLift is a game changer for facility maintenance. It helps you:

- Maximize team efficiency

- Reduce safety incidents

- Minimize operational disruption

- Adapt to any maintenance environment

- Reduce downtime to complete more jobs

Whether you’re managing a single building or an entire campus, the PowerLift is a strategic investment that helps you optimize labor, reduce risk, and increase productivity across your facility.

Interested in learning more about how PowerLift can revolutionize the way you tackle facility maintenance? Follow the link below to browse PowerLift options, see pricing, or reach out to our team.

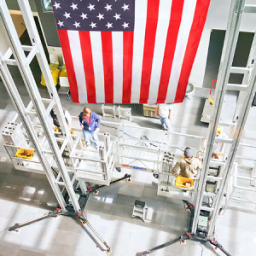

About ReechCraft

Since our founding in 1993, ReechCraft has set itself apart with innovative products and first-rate services. We strive to find new access solutions to meet the needs of every craftsman. If you have questions about any of our American-made products, have a custom application, want to place an order or would like additional information about our dealer program, give us a call at (888) 600-6160 or fill out our online contact form.